Human and animal powered water lifting devices

Practical Action

Advantages

Cheaper construction than most reciprocating

suction and lift pumps

Maintenance using local skills and materials

Long piston stroke gives water delivery of up

to 90 litres/min at 4 metres depth

Disadvantages

Limited to wells of less than 7 metres in

depth

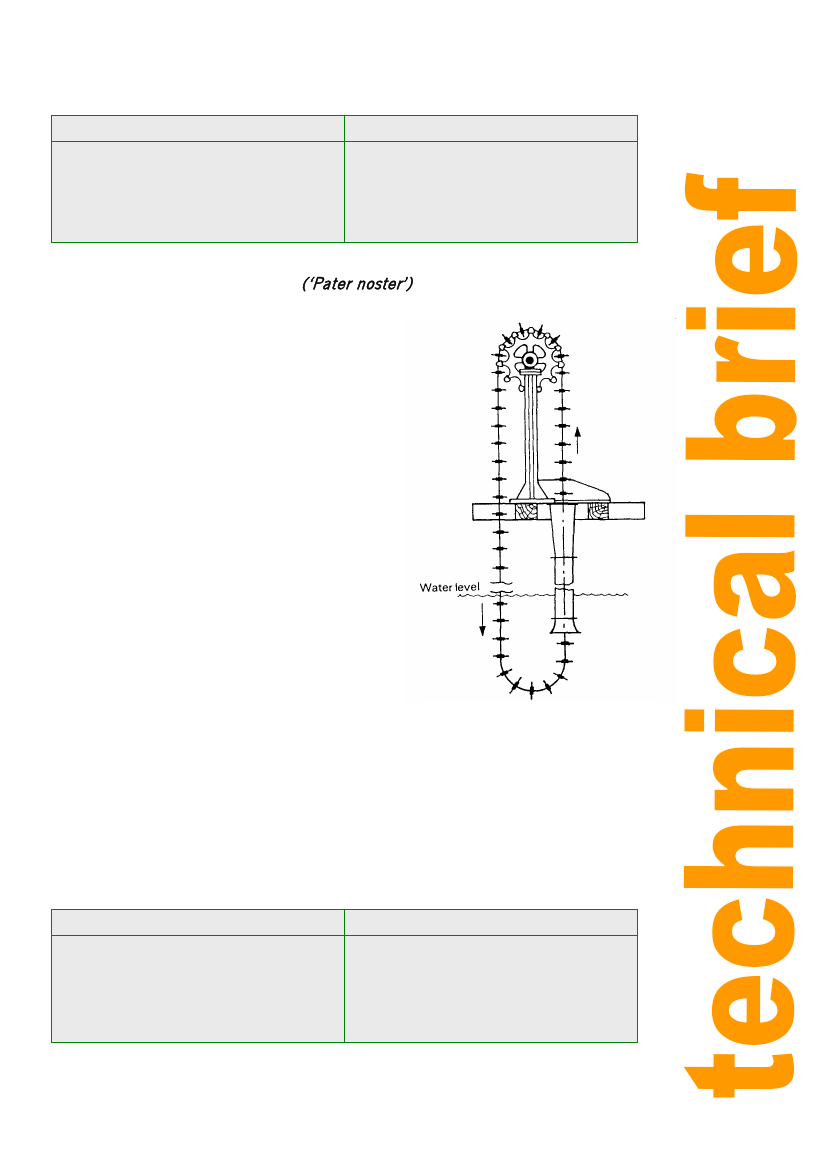

Chain / Rope and Washer Pump (‘Pater noster’)

These pumps have been used in China and Europe for

many centuries. The pump consists of an endless

chain or rope on which washers are mounted at

intervals. The endless chain usually passes over two

drums. The upper drum is above the top of well to

which axle and handle is attached for operation. The

chain with disc passes through a pipe which extends

downward from the top of well to about 0.6 to 0.9m

below the surface of water. As the chain rotates the

discs trap the water in the pipe and carry it to the

surface where it is discharged in a trough.

Although in theory it is possible to construct a vertical

chain and washer pump to raise water to any height,

most do not exceed 35 metres. At this depth the

average yield is calculated as 10 litres/ min. However,

rope pumps more commonly operate at depths of up to

10 m with a water yield of 40 litres/ min. The rope

pump can be adapted to be operated by a horse and

will raise 60 litres/min from a 20 m well.

Chain/Rope and washer pumps require less

maintenance than other equivalent pumps. Their

simple design means that repairs can often be done by

users and require few spare parts. Models can use parts

that incorporate commonly available materials such as PVC

pipe, rope, and old car parts.

Figure 12: Chain and Washer Pump

The main disadvantage of this type of pump for irrigation is that since this is not a pressurised

system it may take time to receive water from the well with the water falling back to the level

of the bottom of the well when not in use.

A variation of this design is called the "dragon-spine" pump, which lies at a shallow angle to

the horizontal. In this case, lifting height is rarely more than 6 metres. However, the design is

very flexible and can easily be adapted to circumstances.

Advantages

Relatively cheap, and easy to manufacture

(for wells down to 35 m rope pumps are five

times cheaper than piston lift pumps.)

Maintenance uses local skills and materials

Disadvantages

Operation limited to depths of up to 35 m.

Initial water delivery is relatively slow at

greater depths.

Frequent simple maintenance required

Medium to high efficiency (50-80%)

9